Technical description

Blue Flame-Resistant Molten Metal Jacket made from permanent flame-resistant fabric, with long sleeves and adjustable with Velcro straps. Front closure with Velcro and a mandarin collar. Stitched with aramid thread.

Application

Protection for the user’s limbs, trunk, and arms against thermal hazards (heat and flames). Protection against thermal agents, heat, and flames ISO11612:2017. Protection for welding and similar processes ISO11611:2015.

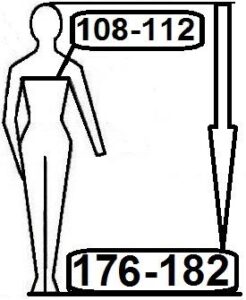

SUPREMA code and sizes

1027 – (S)

1027-1 – (M)

1027-2 – (L)

1027-3 – (XL)

1027-4 – (XXL)

Approval certificate

Blue Flame-Resistant Molten Metal Jacket: 41.796

End of service life for PPE

Replace the Blue Flame-Resistant Molten Metal Jacket when there is fabric rupture or damage.

PPE expiry date

Five (5) years from the manufacturing date. Store the garments in well-ventilated areas, away from heat or moisture.

Cleaning instructions

![]()

![]()

![]()

![]()

— It is important to wash the garments separately from other items, avoiding fiber contamination.

— Never use chlorine-based products during washing, as it compromises mechanical resistance and causes the emergence of unpleasant odors.

— Do not use chlorinated softeners, as these compounds remaining on the garment reduce thermal protection.

— Wash with liquid detergent or neutral powder.

— Do not use bar soap, as it can lead to the formation of insoluble calcium on the fabric, which, being flammable, affects the retardant effect.

— Rinses should be longer to eliminate dirt residues that have been removed from the fabric and may be in the machine, preventing redeposition.

— Dry upside down to increase the durability of your uniform’s color.

— For industrial drying, do not exceed 70ºC.

— Maximum iron temperature of 110ºC.

Attention

All safety clothing is designed to protect the user against specific risks. It is essential to carefully verify if this PPE | Product meets the safety requirements.

A1 – Flame Spread Test conducted with horizontal flame.

Class 1 – Protection against techniques and situations involving low spatter formation in welding, such as: gas welding, MIG welding, micro plasma welding, electric welding.

Class 2 – Protection against techniques and situations involving high spatter formation in welding, such as: electric welding, oxy-acetylene welding, plasma cutting, welding performed in confined spaces, etc.

A value of “0” means the Personal Protective Equipment (PPE) is not suitable for the specific risk.

The letter “X” indicates that the PPE has not been tested for the specific risk in question.